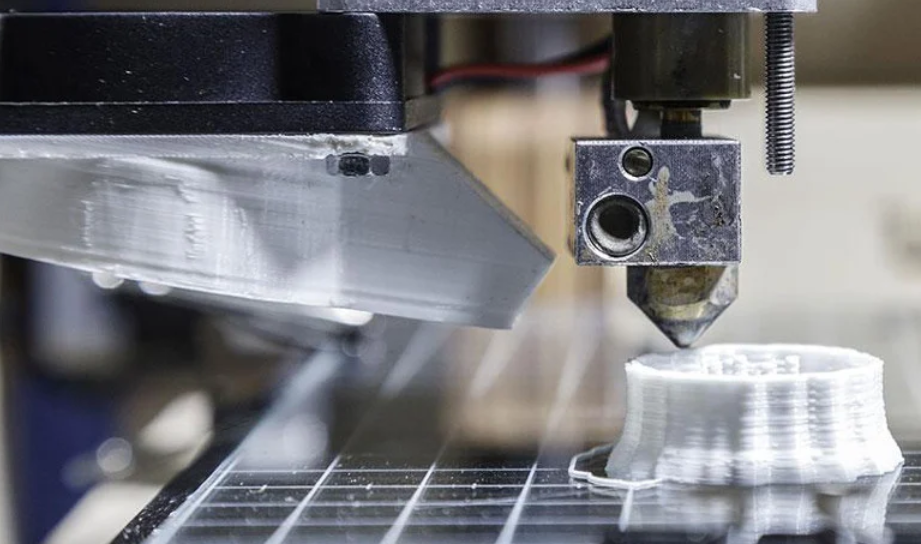

3D printing is transforming the manufacturing landscape in significant ways. It enables rapid prototyping, allowing for innovative designs and complex geometries. This technology not only reduces material waste but also enhances cost efficiency. Additionally, it opens doors for mass customization, aligning production with individual consumer preferences. As manufacturers adapt to these changes, the implications for supply chains and production processes warrant further exploration. What might this mean for the future of industry?

The Impact of 3D Printing on Product Design

As 3D printing technology continues to evolve, its influence on product design becomes increasingly profound.

The ability to engage in iterative prototyping allows designers to explore multiple iterations swiftly, enhancing innovation. This design flexibility empowers creators to experiment with complex geometries and personalized features, ultimately breaking traditional manufacturing constraints.

As a result, 3D printing fosters an environment where creativity can flourish unabated.

Cost Efficiency and Waste Reduction

While traditional manufacturing processes often lead to significant material waste and high production costs, 3D printing offers a transformative solution that enhances cost efficiency and minimizes environmental impact.

By enabling material savings through additive manufacturing, it reduces excess waste.

Additionally, the increased production speed allows companies to respond swiftly to market demands, fostering a more sustainable and financially viable manufacturing landscape.

Customization and Personalization in Manufacturing

Given the increasing demand for tailored products, customization and personalization in manufacturing have emerged as key advantages of 3D printing technology.

This innovation enables mass customization, allowing companies to produce bespoke manufacturing solutions that cater to individual preferences.

As a result, consumers enjoy unique products while manufacturers streamline their processes, enhancing flexibility and responsiveness in a rapidly evolving market landscape.

The Future of Supply Chains and Production Processes

The future of supply chains and production processes is poised for transformation as emerging technologies, such as 3D printing, reshape traditional models.

Digital inventory systems enable companies to manage resources efficiently, while on-demand production minimizes waste and maximizes responsiveness to customer needs.

This shift not only enhances operational flexibility but also fosters innovation, allowing businesses to adapt swiftly in an increasingly dynamic marketplace.

Conclusion

In an age where speed and efficiency reign supreme, one might ironically find that the slow, deliberate artistry of traditional manufacturing has given way to the rapid, almost chaotic creation of 3D printing. This technology, heralded for its innovation, ironically risks overshadowing craftsmanship in favor of mass production and customization. Yet, as manufacturers embrace this revolution, they must ponder whether convenience can truly replace the timeless value of human touch and meticulous design in their pursuit of progress.